- Home

- >

- HFMI treatment

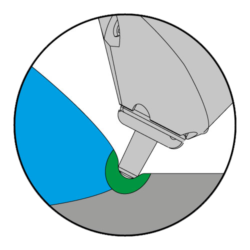

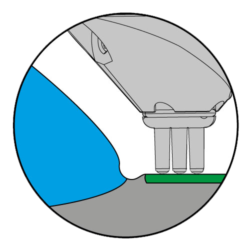

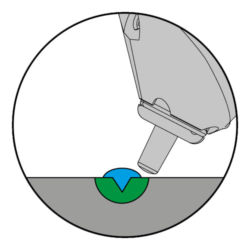

Ultrasonic impact treatment equipment

NOMAD – Portable ultrasonic impact treatment equipment

Our NOMAD equipment is designed and built to guaranty weld impact treatment requirements and needs on site but also in the production workshop. Its strong design, protected by a transport wheelcase and its STRESSONIC® ultrasonic technology ensure easy access to the areas to be treated combined with an optimal quality of treatment.

Our lightweight and portable NOMAD HFMI/UIT equipment is used directly on-site for the treatment of your welded structures (examples: road or rail infrastructure, heavy machinery).

This solution reduces: the resources required for treatment, the infrastructure downtime and the maintenance costs.

Our equipment is designed to be strong enough to withstand outdoor use.

Moreover, our international network, our reliability and our responsiveness mean that we can offer you quality services anywhere in the world.