- Home

- >

- HFMI treatment

Ultrasonic impact treatment

HFMI (High Frequency Mechanical Impact), also known as UIT (Ultrasonic Impact Treatment), is a high-frequency weld impact treatment designed to improve the fatigue resistance of welded structures.

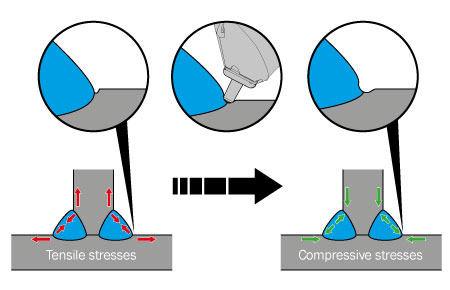

It is a cold mechanical treatment that involves striking the weld toe with a needle (or striker) to create an enlargement of its radius and to introduce residual compressive stresses.

The new recommendation published by the IIW proposes a gain of 4 to 8 fatigue classes depending on the yield strength of the treated steels. The improvements actually noted in the study with our equipment show even more significant improvements.

Principle of ultrasonic weld impact treatment

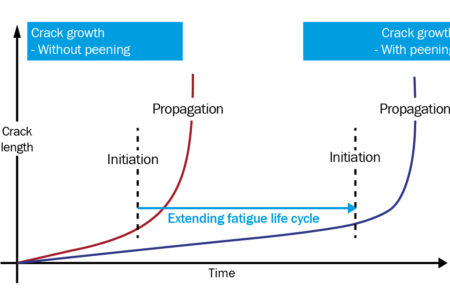

Improvement of the lifetime of a part after ultrasonic weld impact treatment

The creation of superficial compression, by peening, due to the impact of the needles on the material also makes it possible to improve the resistance for stress corrosion cracking.

As this phenomenon occurs on structures and assemblies exposed to corrosive environments, the HFMI/UIT process helps to delay or even eliminate the appearance of cracks.

To know more about the fatigue life improvement of welded structure by ultrasonic needle peening, download our white paper

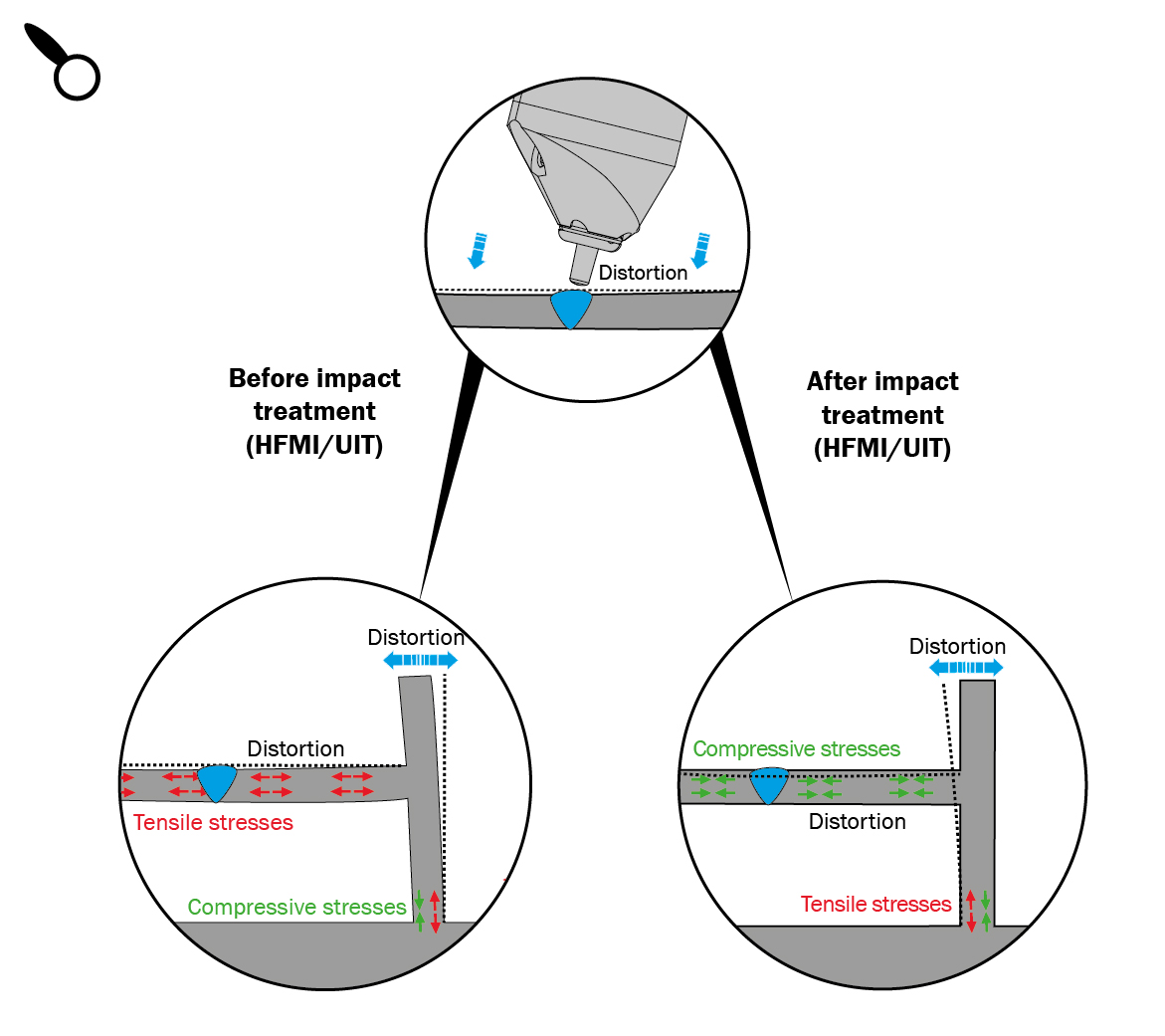

The stresses created by welding processes cause distortions in the welds between the panels.

These well-known distortions occur during the cooling phase of the weld, when the molten metal shrinks, resulting in plastic deformation of the welded metals.

In order to eliminate tensile stress, conventional stress relieving processes are currently applied locally (heating, TIG dressing, etc.). These processes restore a stress level close to 0 MPa at the surface and at a depth but do not correct the defect created by the weld.

Do you notice cracks on your mechanically welded parts and sub-assemblies? The characterisation of your materials and the measurement of residual stresses after welding will enable you to improve the design of your parts and your welding processes.

Download the brochure of our laboratory dedicated to residual stress and material characterisation.

Browse the tabs below to explore in detail the objective, applications, studies and recommendations of ultrasonic impact treatment.

The ultrasonic impact treatment (HFMI / UIT) process not only allows to create residual compressive stresses, which are much more beneficial than stress relief but also allows to straighten the deformations caused by welding. The 2 in 1 effect of ultrasonic impact treatment (HFMI / UIT) is particularly valuable when the aim is to improve the fatigue strength of steels, aluminium and other metal alloys while correcting geometrical defects.

To increase the fatigue life

To increase the fatigue limit

To reduce the weight

To reduce or compensate the distortions induced by the welding

Fatigue resistance technologies, such as NOMAD (ultrasonic weld impact treatment equipment), are regularly and successfully used in many sectors: aerospace, energy, automotive, defence, transportation and infrastructure.

Agricultural machinery

Handling and transport

Industrial equipments

Infrastructures

Naval / Marine

Power Generation

When producing a part or making and assembling a structure, the first step in controlling fatigue resistance is to assess the most critical areas where cracks may appear. Then the best process to apply must be determined. The key to this choice is to assess whether a method of improving fatigue resistance is needed before the onset of major damage. A preventative rather than a corrective approach is much better in order to minimise costs and maximise profits.

Ultrasonic impact treatment is one of the best preventive treatments to improve the fatigue resistance of welded structures.

The effectiveness of the process has been demonstrated in numerous international research studies.

Would you like to know more about the ultrasonic hammering process? Download our dedicated brochures!

Heading “Ultrasonic impact treatment” on the download page

Access to all our download resources