- Home

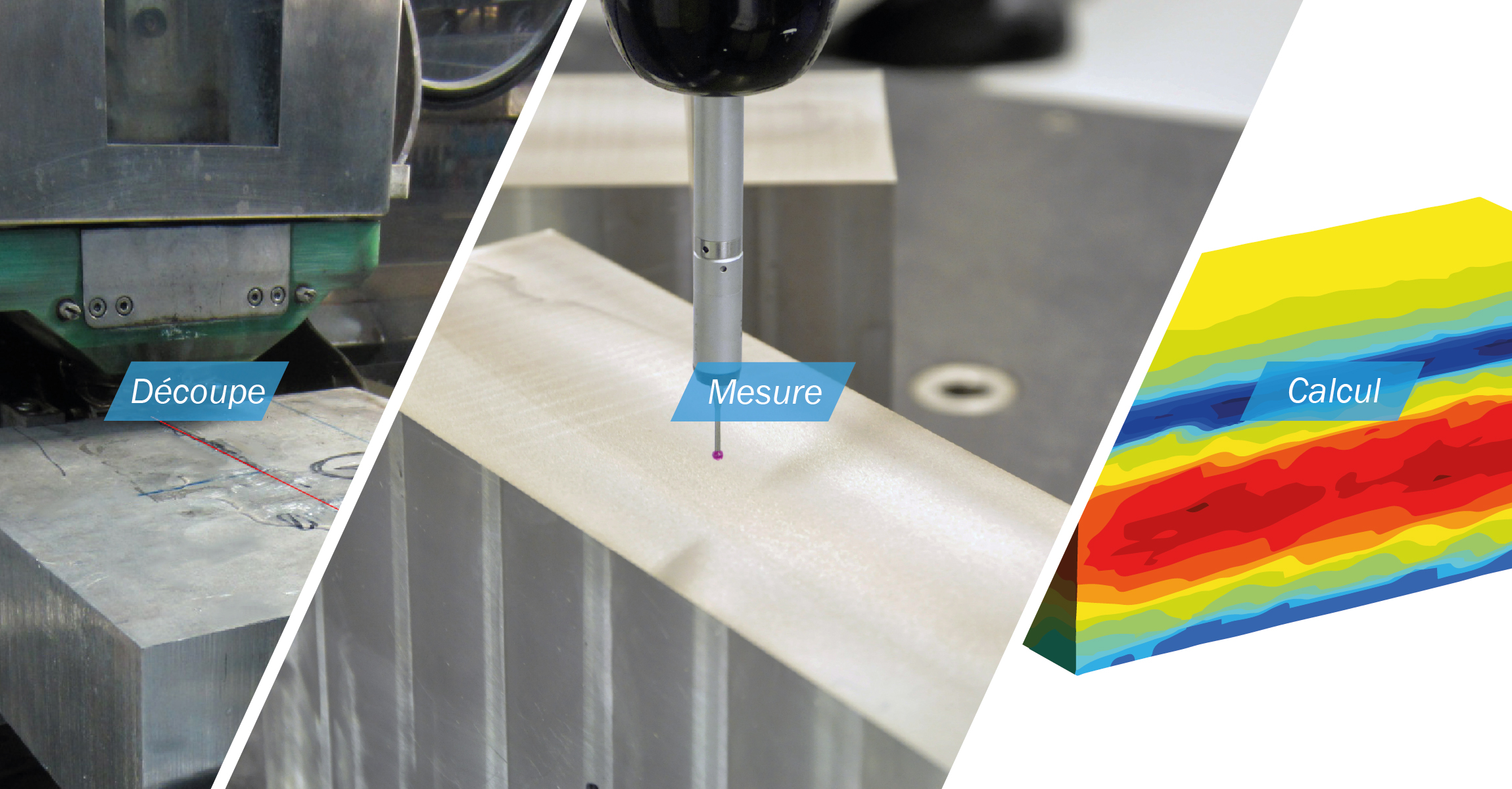

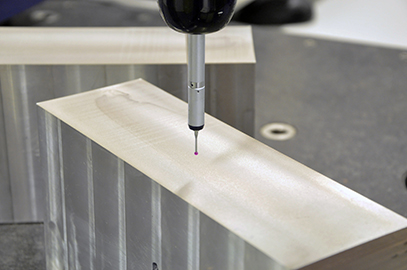

Residual stress measurement

Residual stress measurement laboratory

Our residual stresses and materials characterisation laboratory provides our measurement and analysis services not only in the laboratory but also in-situ at your production site.

Discover our services ou measurement and characterization methods: