- Home

- >

- Residual stress measurement

Eddy current testing for residual stress measurements

Error: Contact form not found.

The testing of residual stresses via multi-frequencies eddy current is a non-destructive method used to :

SONATS provides services of residual stresses testing via eddy current in laboratory or on site. Our portative equipment allows to perform a fast, reliable and in-depth measurement to answer the requirements of your industrial production.

Our control equipment measures on the surface and in-depth of all kind of parts. In case of complex geometries, SONATS designs and manufactures 3D printing tooling to ensure a good repeatability of the measurement.

The RS Profiler analysis technique has been developed in our laboratory in order to correlate data after eddy currents measurement with residual stresses introduced into parts during compressive mechanical treatment (shot peening, roller-burnishing, impact treatment) or machining and the efficiency of thermal and thermochemical treatment.

Testing via multi-frequencies eddy current is often used in the aeronautical, automotive and railway fields but also on assembly line requiring product testing.

In site eddy current measurement on a train in a railway station with a portative testing equipment.

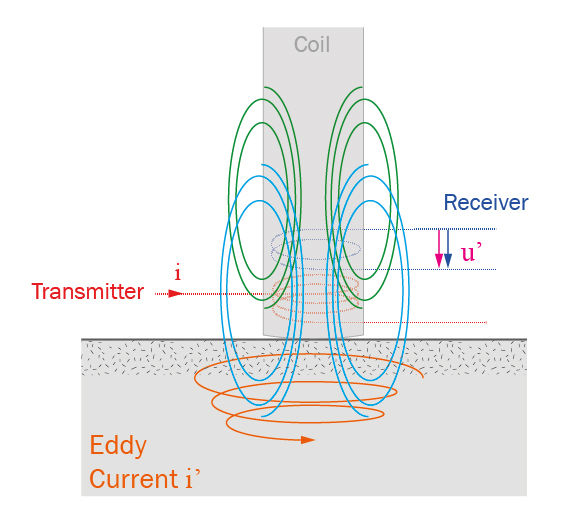

Principle of testing via eddy current method

The measurement of the impedance with coil located on a surface to test allows to evaluate the present residual stresses in the part.

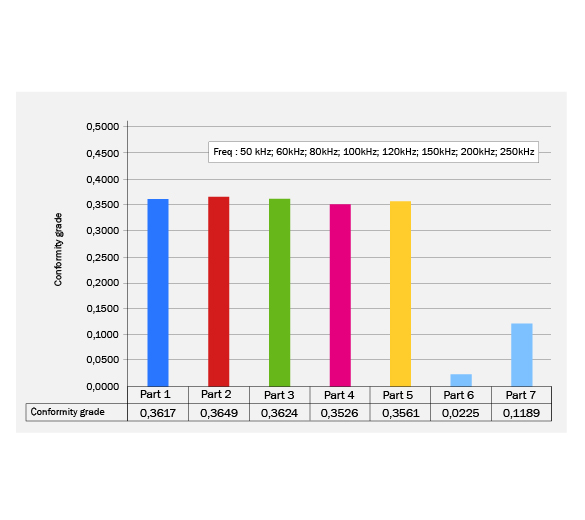

Product conformity control of a steel to evaluate the efficiency of compressive mechanical treatment.

Access to all our download resources