- Home

- >

- Residual stress measurement

Surface and dimensional metrology

Surface and dimensional metrology inspection services

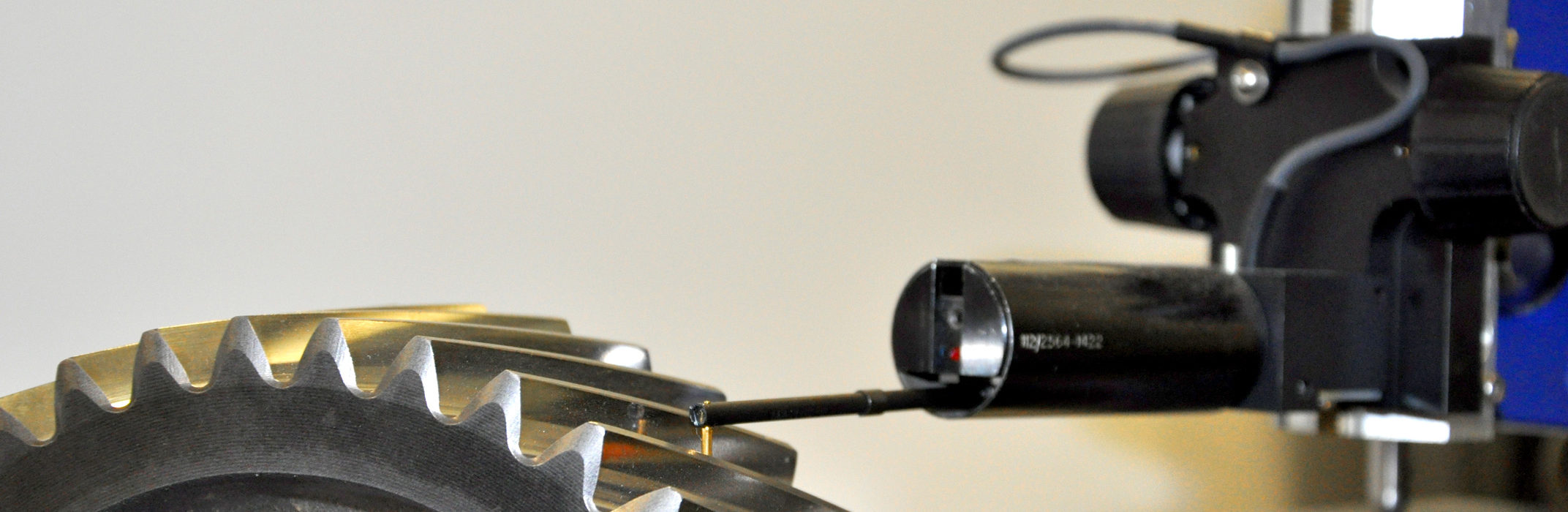

SONATS provides surface and dimensional metrology services, and for these services SONATS has means and tools such as a roughness meter to measure surface roughness parameters (Ra, Rt, Rz, Wa, Wt, etc.). We also have a precision profilometer making it possible to determine the dimensions and the depth of defects (Pt, etc.) as well as the local curvatures of the surfaces (radius and diameter of curvature).

SONATS also has three-dimensional measuring machines: laser scanner, arm, tracker.

These means are usually used to control machined parts.

Dimensional measurements can also be correlated with residual stress measurements to perform complete studies of deformations during manufacturing processes (distortion).

OBJECTIVES OF SURFACE AND DIMENSIONAL METROLOGY

- Understand deformation phenomena,

- Control the material supply,

- Optimise the manufacturing range processes

Three-dimensional measurement equipment: Large capacity coordinate measuring machine (4 x 3 x 1.6 m), three-dimensional Hexagon PCDMIS