- Home

- >

- Shot peening

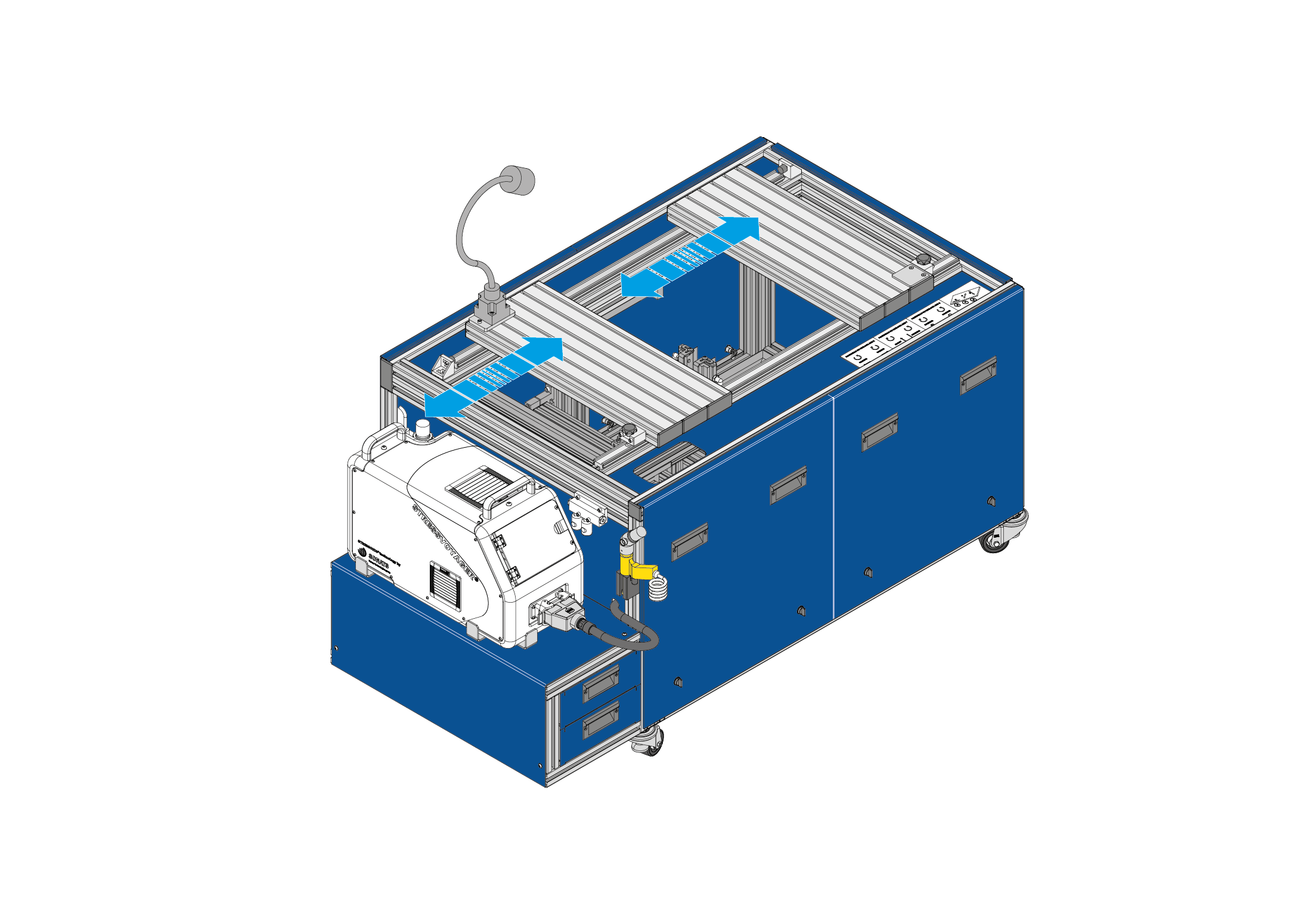

Shot peening bench : semi-mobil equipment

The Shot-Peening Bench : Semi-portable equipment

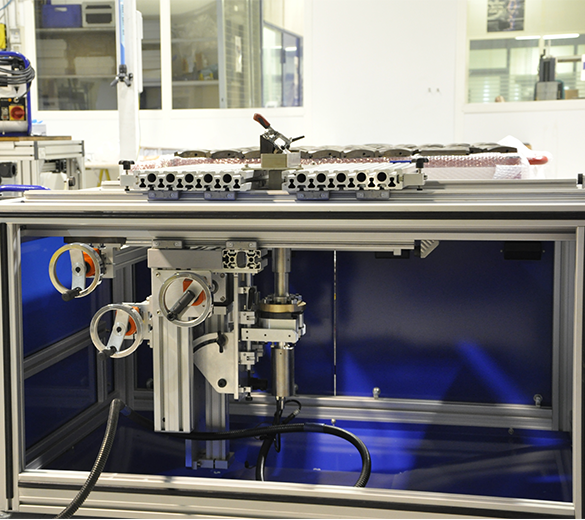

The semi-portable bench is a shot peen equipment, ideal for a production or repair workshop with small and medium-sized production runs. It is also used by research laboratories wishing to produce a small quantity of samples.

Connected to a USP STRESSVOYAGER®, the process remains automatic. In fact, our semi-portable equipment is directly integrated into a shot-blasting bench.