- Home

- >

- Shot peening

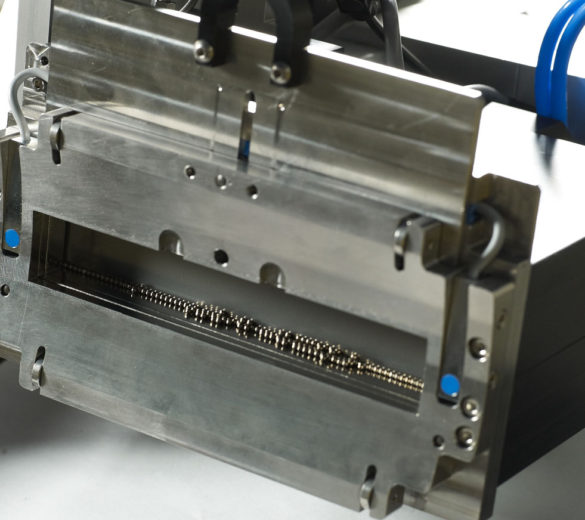

Shot peening service

MRO – Shot Peening Services

SONATS provides its ultrasonic MRO (maintenance, repair and overhaul) shot peening services directly at customer sites worldwide using manual and automated portable equipment. Our subcontracting shot peening activity work is conducted at our Carquefou workshop (44, France), for offloading or series production.

Using manual and automated industrial equipment designed and manufactured by SONATS, our qualified and experienced team of MRO technicians has been providing quality service for over 30 years.

EXAMPLE OF SHOT PEENED PARTS

Our current customers include prime contractors and subcontractors from various industrial sectors :