- Home

- >

- Our markets

Shot peening for the energy and nuclear industry

Safety and reliability are the main concerns of the nuclear industry.

The resistance of materials to thermal fatigue and stress corrosion cracking must be ensured and improved to increase the lifetime and delay crack initiation.

The need to lengthen the lifetime of nuclear power plants requires many preventive operations for critical equipment (pumps, turbines, pipe welds, etc.).

STRESSVOYAGER® solutions can be applied in situ, without creating contamination, release of dust and without using consumables, a major advantage to increasing the lifetime of critical equipment by reducing their downtime.

SONATS provides solutions for the preventive treatment of new products, or for directly shot peening damaged and repaired critical components such as:

Non-exhaustive list.

SONATS solutions have been adopted by several prime contractors and equipment manufacturers in the nuclear sector.

The surface characterisation and residual stress measurement laboratory puts its expertise at the service of the nuclear industry to optimise the manufacture of parts and keep them in good running order following the appearance of stress corrosion cracking.

Examples of parts: stud holes, screw parts, additive manufacturing walls, tubes for the manufacture of heating rods, etc.

Europe Technologies group, member of Nuclear Valley Cluster

Turbines and engines producing energy (Diesel, Gas, Steam, Wind Turbine) are all composed of metal parts exposed to severe environmental conditions (rotation or movement, speed, heat, vibrations, stresses). These components are subject to mechanical fatigue phenomena and so need to be treated in order to increase their lifetime and to prevent breakdowns.

The downtimes generated by failures or preventive maintenance operations of these turbines and engines generate production stoppages and resulting significant operating losses. Reliability and reduction of downtime in the maintenance phase are major issues.

SONATS has developed unique patented solutions for such applications. STRESSONIC® technology is clean, repeatable, quick to set-up and 100% controllable in order to ensure improved performance and availability of equipment.

Indeed, SONATS designs and manufactures manual portable shot peening equipment equipped with STRESSONIC® technology that can be used when manufacturing parts but also during maintenance operations, without requiring complete disassembly of the equipment, which makes it the ideal solution, both technically and economically.

Complete control and mastery of the shot peening process is necessary to ensure and maximise the fatigue resistance of components, generally complex in their geometry.

Conventional shot peening methods do not offer the same level of control as the STRESSONIC® process which is perfectly suitable (reproducibility, highly constant, quality surface condition) to treat high value parts such as:

Non-exhaustive list.

SONATS solutions have been adopted by most prime contractors and equipment manufacturers in the sector.

STRESSONIC® reinforced rack for shot peening in difficult environments

Objective: To reduce thermal fatigue cracking on the rotor of a primary pump.

The team operated on a primary pump rotor for a shot peening service, applied with STRESSONIC® technology, located in the “thermal flange” zone of new parts, and on “hot” parts during maintenance operations. In the latter case, the treatment head can be in contact with the part and the central unit placed up to 10 m away in a protected area.

If the surface of the rotor is cracked, it is first machined, and after the shot peening is carried out automatically directly on the lathe.

Objective: Reintroduce high compressive stresses in areas where cracks have been observed and whose surface has been repaired by machining and/or welding.

The team equipped a robot with a treatment head to be remotely controlled and apply the surface treatment to the machined area.

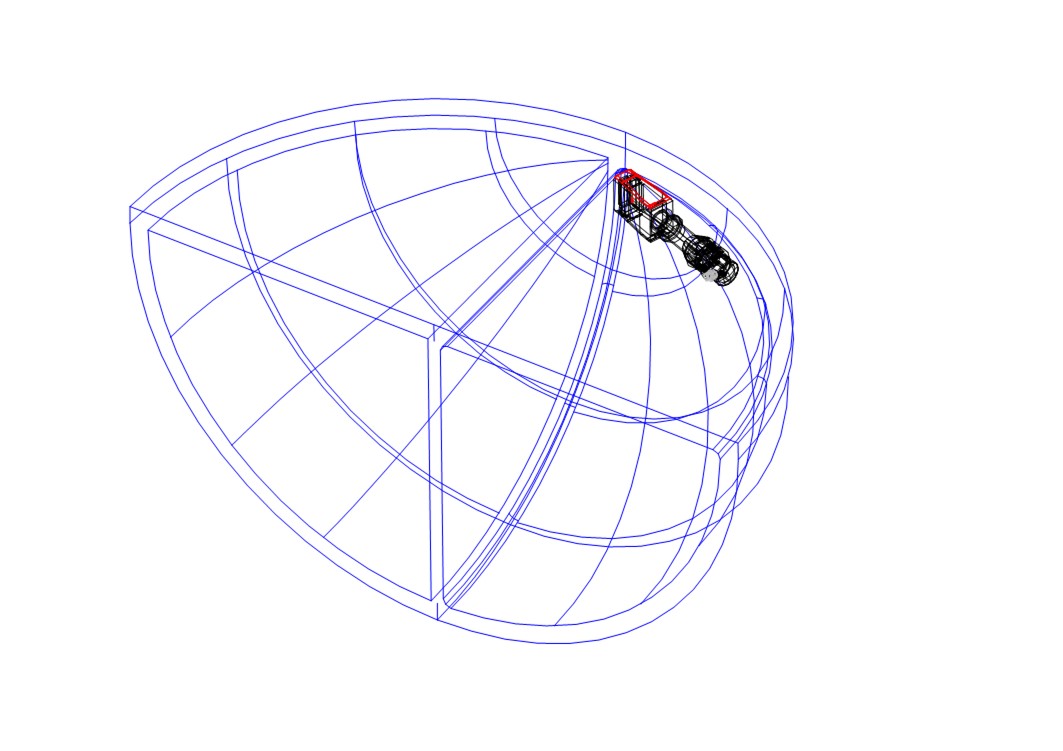

Objective: To increase the maximum load-bearing strength of a defined wind turbine design in order to adapt it to different application conditions.

The technical team assessed the feasibility of introducing beneficial compressive stresses on critical weld areas. We worked with this wind energy company to address welded joints on a nacelle in difficult to access working environments.

The work on the wind turbine nacelle took two weeks and involved two teams using our NOMAD portable ultrasonic weld completion equipment.

Access to all our download resources