- Home

- >

- Our markets

Automotive shot peening

Error: Contact form not found.

The automotive industry is always looking for solutions to reduce energy consumption and increase performance in the face of increasingly demanding demands. Solutions are required that continually push the boundaries of materials in terms of mechanical strength and performance. Compression of the areas most exposed to the effects of fatigue using shot peening and impact treatment ensures that these components comply with pre-defined reliability objectives.

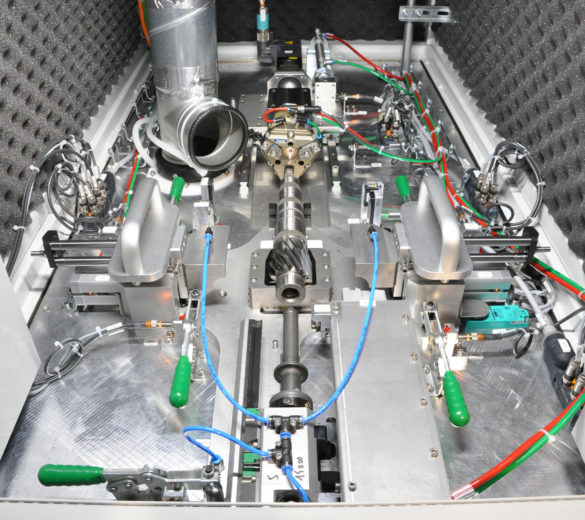

Our customized shot peening machines are automated, to be integrated directly in the lean manufacturing work flows for your parts permitting significantly more control of residual stress levels, surface conditions and a notable reduction of production cycles.

Non-exhaustive list.

The shot peening in engine industry has been used since decades with the aim to enhance the resistance to many failure modes :

By introducing accurately compressive stresses on the surface of the critical parts, initiation and growth of cracks can be significantly reduced.

Removing of reducing surface tensile stresses below critical level will reduce significantly the stress corrosion cracking phenomenon (SCC).

The changes in the surface properties (hardness, roughness, resistance…) will lead to a significant reduction of parts wear and increase their life time.

Access to all our download resources