- Home

- >

- Residual stress measurement

Residual stress measurement

Error: Contact form not found.

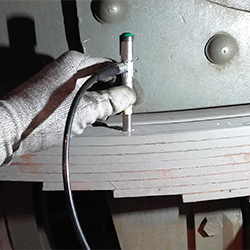

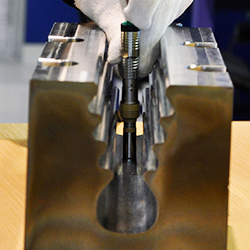

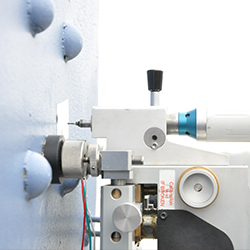

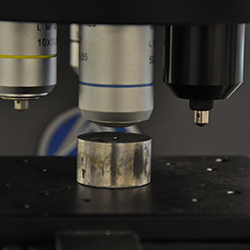

SONATS applies the following methods to measure and analyse residual stresses in its laboratory or on client’s site thanks to potable equipment :

SONATS provides comprehensive expert examination of residual stress and analysis of metallic materials.

Residual stresses cause harmful deformation of parts during manufacture (distortion). They also have an effect on crack resistance: fatigue, stress corrosion, toughness. In addition to metallurgical and dimensional aspects, knowledge and control of residual stresses is therefore important to optimise processes and product quality.

SONATS methods are applicable to all types of parts and materials, regardless of the distribution of residual stresses considered:

Discover a list of examples of analysis and measurement studies for material qualification, part inspection and analysis :

■ Evaluation of compression after shot peening steel, aluminium, titanium and Inconel

Applicable also for: rolling, peening, burnishing, carburising, nitriding, coating, thermal spray, etc.

■ Integrity of machined surfaces, surface stresses due to machining

■ Relationship between residual deformation and stresses (distortion)

■ Residual stresses in additive manufacturing

■ Welding residual stresses and effects of post-treatment

■ The effects of stress relieving or stabilisation heat treatment

Access to all our download resources